Residences at Seventh and Seventh

February 3, 2023

Big Marble Farms

February 24, 2023Can't afford downtime?

Manage your critical Electrical infrastructure with the addition of Infrared Scanning to your scheduled maintenance to reduce or prevent process interruptions and costly repairs.

Infrared (IR) Scanning

Preventative Maintenance

Infrared (IR) scanning is an important tool for electrical preventative maintenance. By using this technology, Spider Electric Ltd. can help clients avoid downtime, improve safety, save energy, and meet regulatory requirements.

Spider Electric Ltd. understands the importance of keeping your business up and running without interruptions. Our trained professionals use high-tech infrared cameras to detect any electrical hotspots, allowing us to pinpoint any potential issues that could lead to costly repairs or unexpected downtime. By identifying potential issues before they turn into major problems, we can help you avoid costly repairs and downtime, allowing your business to continue running smoothly.

- Detect potential problems before they cause downtime or damage

IR scanning can help detect hot spots in electrical systems that may indicate a potential problem. By identifying these hot spots early, we can address the issue before it causes downtime, equipment damage, or costly repairs.

- Improve safety

Hot spots in electrical systems can be a fire hazard. By identifying and addressing them early, we can help prevent fires and improve overall safety.

- Reduce energy waste

IR scanning can identify areas where electrical systems are not working efficiently, such as areas where energy is being lost due to poor insulation. By identifying and addressing these issues, we can help their clients save energy and reduce costs.

- Meet regulatory requirements

Many industries have regulatory requirements for electrical safety and preventative maintenance. By using IR scanning, we can ensure that they are meeting these requirements and avoiding potential penalties or legal issues.

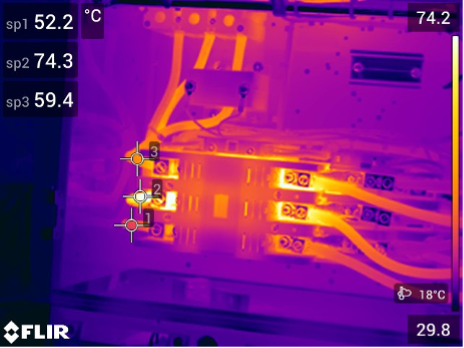

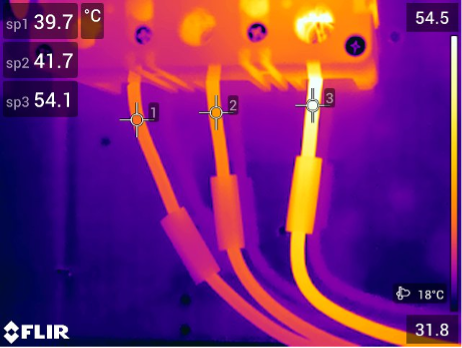

Scanned in the winter, we found a couple of these issues onsite. If the issue had not been discovered and resolved before summer temperatures arrived, these areas could have gotten much hotter and had the potential to cause some major issues.

Before

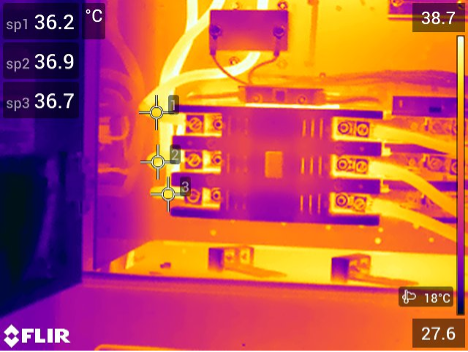

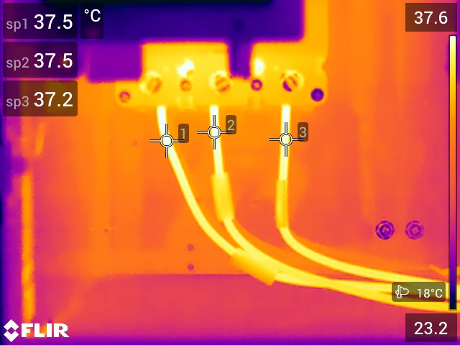

After

Pump building heater #1 at C-oil. Phase C dropped almost 20 degrees after repair.

Before

After

Protect your business and your bottom line.

Contact us to learn more about our top-of-the-line infrared scanning services.